Description

BUSCH R5 - OIL LUBRICATED ROTARY VANE VACUUM PUMPS

THE INDUSTRY STANDARD FOR PERFORMANCE AND RELIABLITY

Manufacturers: Busch - Germany

Model: R5 Series (R 5 0010/0016 C, R5 RA 0155 A, R 5 RA 0400 - 0630 C, R5 RAH 200 / 300 A, R 5 RA 0025/0040 F, R 5 RA 0160 - 0302 D, R 5 RA 0750 A, R 5 RB 0021 C, R 5 RB 0021 C, R 5 RA 0063/0100 F, R 5 0165 - 0305 D, R 5 RA 1000/1600 B)

Nominal pumping speed: 4 - 1800 m3/h

The robustness and operational reliability of oil-lubricated R 5 rotary vane vacuum pumps have long made them the industry standard. Every day over 2.5 million R 5 vacuum pumps worldwide provide dependable service under the harshest industrial conditions.

Safe and cost-effective

Rotary vane technology has been continuously developed and optimised by Busch over the decades, with the emphasis on operational reliability and efficiency. R 5 rotary vane vacuum pumps are known throughout the industry for their modern and energy-efficient vacuum generation, in a wide range of applications. Whether for intermittent or continuous use, you can rely on the R 5.

Proven

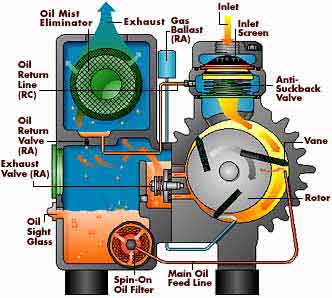

These compact R 5 vacuum pumps owe their robustness to proven rotary vane technology with recirculating oil lubrication. This guarantees a consistently high vacuum level which can cope with the toughest operating conditions. When fitted with a gas-ballast valve (optional), vapours can be pumped without condensation.

|

|

The highest pumping speed at the best ultimate pressure is guaranteed by the two largest sizes of the proven series of R 5 rotary vane vacuum pumps.

Robustness and reliability of operation

are the outstanding properties of R 5 rotary vane vacuum pumps. These are some of the reasons why proven Busch technology has long been established as the industry standard. Over two million R 5 vacuum pumps are in use worldwide in industrial day to day business.

Operationally reliable and cost-effective

The rotary vane technology has been continuously developed and optimised by Busch for 50 years, with constant focus on both economy and reliability of operation. High efficiency and energy-efficient drive units are the positive results of this development. These vacuum pumps are fitted with heavy-duty carbon fibre composite vanes as standard.

These Busch vanes have been developed for tough operation of R 5 vacuum pumps and are manufactured exclusively at our own plant. The highly efficient exhaust filters are also a special development, as they guarantee optimum oil separation of even the smallest oil particles from the exhaust.

Service-friendly

Maintenance can easily be carried out by the operator. Apart from the change of oil and filters at regular service intervals, no further maintenance is neccessary.

R 5 rotary vane vacuum pumps are known throughout the industry for modern and energy-efficient vacuum generation suitable for all kinds of applications whether being used intermittently or around the clock, you can rely on the R 5.

Technical specifications

The rotary vane technology enables technically simple assembly of the vacuum pumps. The consistently high vacuum level in continuous operation is guaranteed by the circulating oil lubrication, perfectly coordinated materials and state-of-the-art and precise manufacturing. The oil separator, which is mounted on as standard, ensures clean, oil-free exhaust thanks to its sophisticated extractor system with integrated oil return. When fitted with gas ballast valves (optional), even larger amounts of vapour can be pumped. A non-return valve in the inlet bushing prevents air from flowing back into the vacuum chamber during the vacuum pump’s shut-down period. The drive unit is driven by a directly flange-mounted standard electric motor, efficiency class IE2.

Accessories/technical options

• Gas ballast valve

• Various inlet filters

• Filter pressure gauge

• Oil level switch

• Vacuum regulating unit

• Vacuum oils for all applications