Description

BUSCH DOLPHIN - LIQUID RING VACUUM PUMPS AND COMRESSORS

Manufacturers: Busch - Germany

Model: DOLPHIN Series (Dolphin LA 0053 - 0143 A, Dolphin LA 0756/0906 A, Dolphin LB 3809/4409 A, Dolphin LB 0265 - 0425 A, Dolphin LA 1157 - 1807 A, Dolphin LA 0710/1111 A, Dolphin LA 1908 - 2808 A, Dolphin LB 0063 - 0184 A, Dolphin LB 0710/1011 A, Dolphin LB 3809/4409 A, Dolphin LB 0265 - 0425 A, Dolphin LB 0857 - 1757 A, Dolphin LB 0526/0726 A, Dolphin LB 2108 - 3108 A, Dolphin LX 0030/0055 B, Dolphin LX 0110-0180 B, Dolphin LX 0260-0430 B).

- Ultimate Pressure: 33 - 150 hPa (mbar)

- Overpressure: 2 bar (g)

- Nominal pumping speed: 25 - 10000 m3/h

Dolphin pumps are the robust and proven liquid ring vacuum pumps from Busch. They are available as single or two-stage pumps with a directly flange-mounted motor, or assembled on a base plate. Their proven operating principle allows them to be used in all industrial sectors. Even critical applications such as the evacuation of saturated gases and vapours are easily managed by Dolphin liquid ring vacuum pumps.

Reliable

Dolphin liquid ring vacuum pumps impress with their robust design. Thanks to the modular design of the base plate versions, custom systems can be produced easily to match specific processes.

Application-orientated

Dolphin liquid ring vacuum pumps are designed for continuous operation. Several sizes and versions are available, and the wide range of accessories and different workshop options allow vacuum pumps to be adapted to any process. Dolphin LX liquid ring vacuum pumps are also available in ATEX versions. Dolphin liquid ring technology can also be used for overpressure generation: Busch supplies Dolphin liquid ring compressors for overpressures of up to 2 bar (g).

Application oriented

Dolphin vacuum pumps are designed for continuous operation. The various designs and accessories allow the pumps to be easily adaptable for any process.

Reliable

due to robust design and application-oriented materials of construction.

Well proven

In the base plate version the modular design allows various assemblies to suit many applications.

Technical Specifications

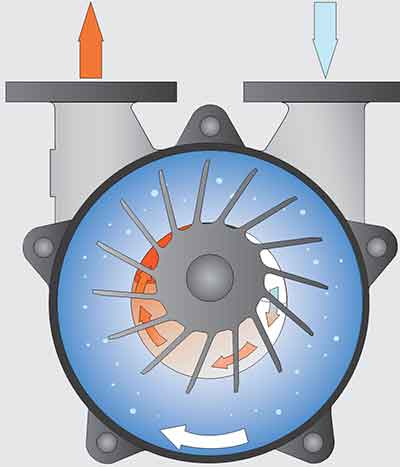

Liquid ring vacuum pumps normally operate with water as the operating medium. An eccentrically installed impeller rotates in the casing partly filled with liquid. By the rotational movement of the impeller and the resulting centrifugal force the liquid within the cylinder forms the so called liquid ring. Gas is conveyed in the spaces between the single vanes and the liquid ring. Due to the eccentric installation of the impeller the spaces enlarge and the process gas is sucked in through the suction slot. As the impeller further rotates, the spaces are reduced, so that the gas is compressed and discharged through the discharge slot. The vacuum pump can be operated with water recirculation, open or closed loop circuit.

Once through system

The service liquid is constantly fed through the pump and is discharged together with the gas.

Partial recovery system

Within this system the service liquid is discharged to a vessel which allows separation of the gas and liquid. The recirculated liquid is drawn back into the pump as service liquid along with fresh liquid to replace the amount discharged to waste via the vessel overflow.

Total recovery system

In a total recovery system the service liquid and gas are separated in a vessel, a heat exchanger is added to remove the heat of compression prior to re-use of the service liquid, which is fed back to the pump.

Accessories/ technical options

• Liquid separators

| Technical Data | Dolphin LA 0756 A | Dolphin LA 0906 A | ||

|---|---|---|---|---|

| Nominal pumping speed | m3/h | 50 Hz | 750 | 900 |

| Ultimate pressure | hPa (mbar) | 50 Hz | 130 | 130 |

| Nominal motor rating | kW | 50 Hz | 22 | 30 |

| Nominal motor speed | min-1 | 50 Hz | 1450 | 1450 |

| Noise level (ISO 2151) | dB(A) | 50 Hz | 75 | 75 |

| Weight approx. | kg | 306 | 338 | |

| Dimensions (L x W x H) | mm | (840-1000) x 400 x 630 | (920-1080) x 400 x 630 | |

| Gas inlet / outlet | DN 100 KF / DN 100 KF | DN 100 KF / DN 100 KF |

Applications:

- Chemical industry

- Pharmaceutical industry

- Oil and gas

- Plastics industry

- Beverage industry

- Environmental technology

- Paper industry

- Medical technology

- Food technology

- Brick making

- Drying/impregnation

- Absorption/degassing

- Metallurgy