Description

UF MEMBRANE (ULTRAFILTRATION) SYNDER - USA

Manufacturers: Synder - USA

1. Intro

Synder Filtration offers the widest range of ultrafiltration membranes available to provide maximum flexibility in solving unique process challenges. Available in both spiral wound and flat sheet membrane configurations, Synder can customize ultrafiltration membranes and membrane systems to meet the specific application goals of our customers.

Overview

Ultrafiltration membranes are capable of separating larger materials such as colloids, particulates, fats, bacteria, and proteins, while allowing sugars, and other low molecular weight molecules to pass through the membrane.

With a pore size range between 0.01 to 0.1µm, ultrafiltration membrane pore sizes fall between that of nanofiltration and microfiltration. UF membranes typically operate between 50 – 120 PSI (3.4 – 8.3 bar) and are dependent on transmembrane pressure to drive the separation process. Other polymeric ultrafiltration membrane characteristics include robust chemical and temperature resistance, and low fouling tendencies if proper pretreatment is employed.

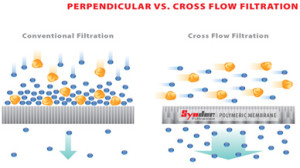

Cross Flow Filtration & Process Techniques

Cross Flow Ultrafiltration (also known as Tangential Flow Ultrafiltration) is a separation process where the feed stream is in parallel to the membrane surface, which helps to control the formation of the gel layer, greatly improving flux stability and membrane life vs. perpendicular flow systems.

As opposed to conventional filtration which causes a quick build-up of solids onto the membrane surface, cross flow filtration increases the passage of permeate through the membrane and overall flux efficiency.

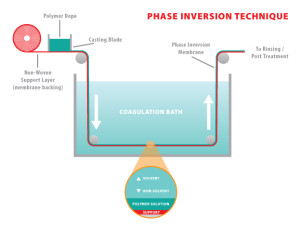

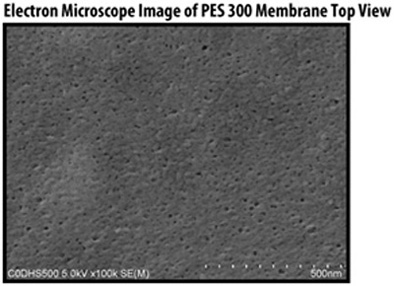

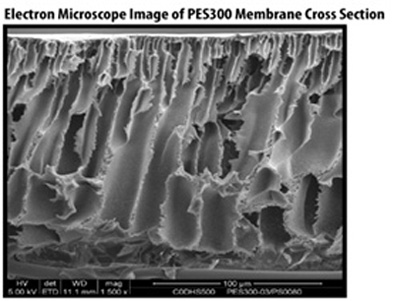

Both sanitary and industrial ultrafiltration membranes are comprised of a semi-permeable, polymeric membrane layer cast onto a uniform substrate, or backing material. Synder Filtration employs phase inversion to extra solvents out of the liquid polymer dope that has been cast onto the backing material. As the solvents are extracted, the polymer solidifies forming an asymmetric pore structure, which is ideal for controlling rejection at the surface, while promoting maximum throughput of permeate.

UF Products

Synder Filtration offers an extensive range of ultrafiltration molecular weight cut-offs available in both flat sheet and spiral-wound configurations. These are suitable for use in both sanitary and industrial-grade applications. Sanitary membranes meet compliance with FDA standards listed in CFR Title 21, 3-A Sanitary Standards No. 45-02, and USDA Sanitary Standards.

Many of these membrane formulations were developed specifically by a customer request. Because Synder is financially independent and family owned, we are able to reinvest heavily in our research and application development programs. As a result, membranes and spiral elements can be customized with great speed and flexibility, in order to better serve our valued customers. For more information about our custom membrane development program.

| Membrane | Type | Polymer |

MolecularWeight Cut-Off |

| XT | UF* | PES | 1,000 |

| VT | UF* | PES | 3,000 |

| MT | UF* | PES | 5,000 |

| ST | UF* | PES | 10,000 |

| SM | UF* | PES | 20,000 |

| MK | UF* | PES | 30,000 |

| MQ | UF* | PES | 50,000 |

| LY | UF* | PES | 100,000 |

| LV | UF* | PES | 200,000 |

| LX | UF* | PES | 300,000 |

| PZ | UF* | PAN | 30,000 |

| PY | UF* | PAN | 100,000 |

| PX | UF* | PAN | 400,000 |

| V3 | UF*1 | PVDF | 30,000 |

| V4 | UF*1 | PVDF | 70,000 |

| V5 | UF*1 | PVDF | 200,000 |

| V6 | UF*1 | PVDF | 500,000 |

| V7 | UF*1 | PVDF | 800,000 |

| BN | UF* | PVDF | 50,000 |

| BY | UF* | PVDF | 100,000 |

| BX | UF* | PVDF | 250,000 |

| A6 | UF* | PVDF | 500,000 |

*PHT (High Temperature/High pH) Models Also Available

UF Applications

Synder Filtration currently offers over a dozen different types of ultrafiltration membranes, all of which exhibit excellent pH and temperature resistance, in addition to low fouling tendencies. Some common applications of Synder’s UF membrane technology include:

|

Industrial Process and Wastewater |

|

Dairy |

|

Biotech / Pharmaceutical

|

|

Food & Beverage

|

|

Automotive / Industrial

|

2. Ultrafiltration: Flat Sheet Membranes

In certain high solids applications, flat sheet ultrafiltration membranes provide excellent performance (membrane life vs. operating cost). Unlike hollow fiber membranes, flat sheet ultrafiltration membranes have a strong support material in which the polymeric membrane layer is rooted that increases physical durability substantially.

Synder Filtration offers a comprehensive line of both dry and wet ultrafiltration flat sheet membrane available in a wide range of molecular weight cut-offs. With product sizes ranging from one square foot to thousands of linear feet, Synder can supply UF flat sheet membranes for process research, pilot testing, spiral element winding, and for use in plate & frame membrane systems.

| Membrane | Type | Polymer | Molecular Weight Cut-Off | |

| XT | UF* | PES | 1,000 | |

| VT | UF* | PES | 3,000 | |

| MT | UF* | PES | 5,000 | |

| ST | UF* | PES | 10,000 | |

| SM | UF* | PES | 20,000 | |

| MK | UF* | PES | 30,000 | |

| MQ | UF* | PES | 50,000 | |

| LY | UF* | PES | 100,000 | |

| LV | UF* | PES | 200,000 | |

| LX | UF* | PES | 300,000 | |

| PZ | UF* | PAN | 30,000 | |

| PY | UF* | PAN | 100,000 | |

| PX | UF* | PAN | 400,000 | |

| V3 | UF*1 | PVDF | 30,000 | |

| V4 | UF*1 | PVDF | 70,000 | |

| V5 | UF*1 | PVDF | 200,000 | |

| V6 | UF*1 | PVDF | 500,000 | |

| V7 | UF*1 | PVDF | 800,000 | |

| BN | UF* | PVDF | 50,000 | |

| BY | UF* | PVDF | 100,000 | |

| BX | UF* | PVDF | 250,000 | |

| A6 | UF* | PVDF | 500,000 |

*PHT (High Temperature/High pH) Models Also Available

Synder typically holds a large inventory of flat sheet membrane rolls in order to provide our customers with the fastest possible lead times. We take pride in our ability to provide timely, knowledgeable, and friendly service, and aim to do business the right way.

Ultrafiltration flat sheet membranes may also be provided in specific die cut patterns after an initial feasibility assessment is completed by Synder’s experienced technical staff. In addition, Synder offers a membrane development program for custom membranes uniquely designed for specialty processing applications.

3. Membrane Filters: Spiral-Wound Ultrafiltration Elements

Ultrafiltration membranes are available in many different configurations, including hollow fiber, tubular, flat sheet, and spiral-wound. When total suspended solids are mostly removed with pre-filtration, spiral-wound ultrafiltration elements are preferred choices because they provide a balanced combination of active membrane area density, physical durability, membrane life, and unit cost.

Ultrafiltration membranes are available in many different configurations, including hollow fiber, tubular, flat sheet, and spiral-wound. When total suspended solids are mostly removed with pre-filtration, spiral-wound ultrafiltration elements are preferred choices because they provide a balanced combination of active membrane area density, physical durability, membrane life, and unit cost.

Synder Filtration currently offers twenty-two different molecular weight cut-offs and sizes for spiral wound ultrafiltration elements, available in both sanitary and industrial grades. With molecular weight cut-offs ranging from 1,000 – 500,000Da and membranes available in both PES and PVDF polymer materials, Synder’s ultrafiltration membranes offer great flexibility and pore selectivity. More information can be found in our sanitary and industrial catalogs.

| Membrane | Type | Polymer | Molecular Weight Cut-Off |

| XT | UF* | PES | 1,000 |

| VT | UF* | PES | 3,000 |

| MT | UF* | PES | 5,000 |

| ST | UF* | PES | 10,000 |

| SM | UF* | PES | 20,000 |

| MK | UF* | PES | 30,000 |

| MQ | UF* | PES | 50,000 |

| LY | UF* | PES | 100,000 |

| LV | UF* | PES | 200,000 |

| LX | UF* | PES | 300,000 |

| PZ | UF* | PAN | 30,000 |

| PY | UF* | PAN | 100,000 |

| PX | UF* | PAN | 400,000 |

| V3 | UF*1 | PVDF | 30,000 |

| V4 | UF*1 | PVDF | 70,000 |

| V5 | UF*1 | PVDF | 200,000 |

| V6 | UF*1 | PVDF | 500,000 |

| V7 | UF*1 | PVDF | 800,000 |

| BN | UF* | PVDF | 50,000 |

| BY | UF* | PVDF | 100,000 |

| BX | UF* | PVDF | 250,000 |

| A6 | UF* | PVDF | 500,000 |

*PHT (High Temperature/High pH) Models Also Available

Synder’s sanitary ultrafiltration spiral-wound elements are compliant with FDA (CFR Title 21), USDA 3-A (Sanitary Standards No. 45-02) and are designed for a variety of sanitary and industrial applications, such as:

- Whey Protein Concentrate/Isolate concentration

- Milk protein concentration/standardizing

- Brine clarification

- Casein/Whey Fractionation

- Enzyme/protein concentration

- Endotoxin & pyrogen removal

- Antibiotics production

- Blood plasma processing

- Gelatin concentration & purification

- Plant extract processing

- Corn wet milling

- Fruit juice concentration

- Electrocoat painting

- Industrial wastewater treatment

Synder can create custom spiral wound elements and provide membrane developmentservices for specific application processes upon request. Please contact us to find out more. You will receive a personal response from one of our team members within 24 hours.

4. Ultrafiltration Membrane Systems: Pilot & Full Scale

Synder Filtration designs and fabricates a wide range of tangential flow ultrafiltration membrane systems designed for specialty process applications. UF systems feature spiral-wound membranes, and can be combined with microfiltration, nanofiltration, and reverse osmosis systems and pretreatment equipment to deliver a complete turn-key separation process.

Synder Filtration designs and fabricates a wide range of tangential flow ultrafiltration membrane systems designed for specialty process applications. UF systems feature spiral-wound membranes, and can be combined with microfiltration, nanofiltration, and reverse osmosis systems and pretreatment equipment to deliver a complete turn-key separation process.

The first step in system manufacturing is meeting with our customers to gain a thorough understanding of the process goals in mind. Synder’s development team then prepares a comprehensive test plan, including feasibility and pilot testing, to use as a basis for projections and full-scale system designs. Synder offers an array of ultrafiltration pilot systems with a full range of capabilities, controls sophistication, and price points.

Below are some examples of current pilot units available for rent, and commercial full-scale systems purchased over the past few years.

With operating pressures up to 120psi and durable SS304 or SS316 stainless steel construction, UF pilot tests can be performed under a wide range of operating conditions. Pilot studies are conducted either in the field or at Synder’s Application Development Center in Vacaville, California.

IP55 rated UF system for the oil & gas refinery industry equipped with a temperature/control panel regulated through A/C, and specialized pumps controlled by VFD

UF-MF system used in the biotech industry containing individually isolatable bag filters & UF housings, as well as a pump with a soft starter.

EDUF system for use in the E-Coat industry containing basic temperature regulation.

Once the test results are collected, the engineering team engages to design the full scale membrane process solution. As an ultrafiltration systems manufacturer, Synder has the capability to fabricate, install, commission and support full-scale and multi-process (reverse osmosis, nanofiltration, ultrafiltration, and microfiltration) membrane systems. In every step of the process, we aim to deliver timely, knowledge, friendly service, and ultimately, application profitability to our customers.