Description

DEBEM DRUM TRANSFER PUMPS: TR

|

|

|

| Electric Motor | Pneumatic Motor | Pump casing |

Manufacturers: DEBEM - Italy

Model: TR

TRANSFER PUMPS

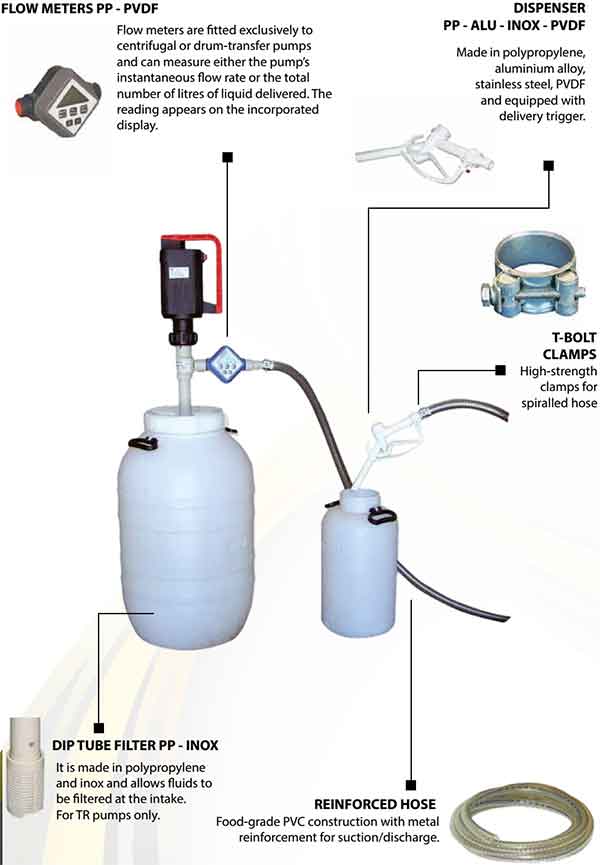

These portable drum-transfer immersion pumps are designed to pump corrosive liquids.

Their special shape ensures that any spillages are collected in the drum.

Available with fully-interchangeable electric or pneumatic motor, these pumps have an open impeller that allows continuous pumping of clean corrosive liquids having apparent viscosity of up to 600 cps with 500-watt electric and pneumatic motor (at 20°C) and 900 cps with 800-watt electric motor (at 20°C). TR-EL series pumps driven by an electric motor are also fitted with a safety cut-out switch that prevents accidental restart after a power outage.

|

|

Drum transfer pumps

|

TR MOTORS

|

model

|

flow rate

|

construction materials

|

|

80 l/min

|

|||

|

120 l/min

|

|||

|

80 l/min

|

|||

|

90 l/min

|

|||

|

80 l/min

|

|||

|

90 l/min

|

|||

|

TR PUMPS

|

model

|

flow rate

|

construction materials

|

|

PP

|

|||

|

Aisi 316

|

|||

|

Aisi 316

|

|||

|

PVDF

|

Main features

- Available in PP, PVDF e Aisi 316

- Inexpensive;

- Portable;

- Handles corrosive liquids;

- Viscosity up to 900 cps;

- Available with either electric or pneumatic motor;

- Adjustable flow rate (pneumatic version);

- No mechanical seals;

- Easily dismantled;

- Dip tube length = 900 mm or 1200 mm;

- Flow rate up to 90 l/min.

Description of the pumps

|

These drum transfer pumps consist of a dip tube the end of which houses the open impeller that is secured to the driveshaft connected to the pump by means of a ring nut, whilst transmission is provided by a shaft coupling. A = drive coupling |

|

How it works

The impeller is integral with the shaft and coupled to the electric or pneumatic motor that makes it rotate, thus creating the centrifugal effect.

Installation

|

TR drum transfer pumps should only be used with the shaft positioned vertically and the pump immersed in the drum, whilst liquid must be present. Running dry or with air bubbles can cause damage to the internal shaft guide bushing. |

|

chemical compatibility

The type of liquid, temperature and working environment are factors to be considered when deciding on the best choice of construction materials for the pump and its correct chemical compatibility. The table below gives some examples of the most commonly-used substances: