Description

CLAW VACUUM PUMPS AND COMPRESSORS

BUSCH: MINK Series

Manufacturers: Busch - Germany

Model: MINK Series ( Mink MI 2124/2122 BV, Mink MM 1402/1502 AV, Mink MM 1104 - 1142 BV, Mink MV 0040 - 0080 C, Mink MM 1324 - 1322 AV, Mink MV 1202 A)

|

|

Overpressure: 2.0 bar(g)

Nominal pumping speed: 60 - 1200 m3/h

Oil- and contact-free operation

Mink claw vacuum pumps have been developed specifically for industrial applications in which constant vacuum, high pumping speed and completely oil-free compression are essential. Mink claw vacuum pumps operate contact-free; neither oil nor operating fluids are required during compression.

Highly efficient

The sophisticated claw technology of Mink claw vacuum pumps permits extremely high efficiency levels to be achieved, reducing energy consumption and increasing performance. These vacuum pumps operate contact-free and require almost no maintenance. In practice, this means 60% lower energy and operating costs compared to conventional vacuum generators.

The same claw technology is also used for Mink compressors. They provide oil-free overpressure at up to 2 bar (g) and volume flows of up to 580 m3/h.

Due to the sophisticated claw vacuum technology, Mink vacuum pumps achieve an extremely high level of efficiency, which has a positive effect on energy consumption and performance. In practice, this means energy savings of up to 60% compared to conventional vacuum technology when operated at the same pumping speed.

An additional benefit of claw vacuum technology is the virtually maintenance-free operation due to the non-contact operating principle: none of the moving parts inside the vacuum pump come into contact with one another, meaning there is no wear at all.

The need for maintenance, such as the inspection or replacement of worn parts, is completely eliminated. Due to the completely dry compression without the need for any operating fluids in the compression chamber, there are no costs for purchase, provision or disposal. Mink claw vacuum pumps are air-cooled.

The high operational reliability and long life cycles of Mink claw vacuum pumps are also a result of their non-contact compression without operating fluids. Due to wear-free operation, vacuum and suction performance remain consistently high throughout a life cycle of the pump. A smart silencer concept enables quiet operation.

Technical specifications:

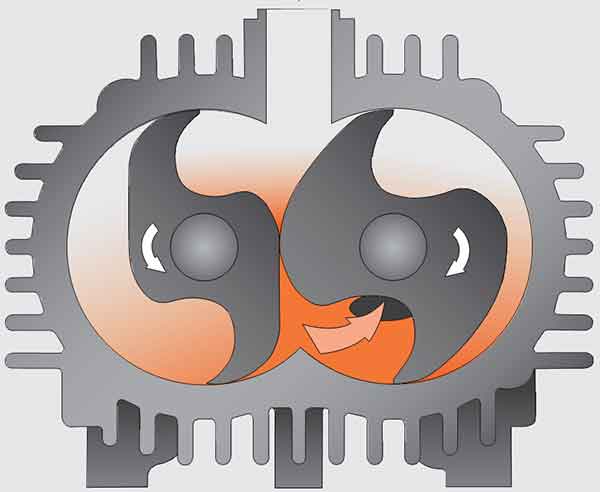

With Mink vacuum pumps, two claw-shaped rotors turn in opposite directions inside the housing. Due to the shape of these claw rotors, the air or gas is sucked in, compressed and discharged. The claw rotors do not come into contact either with each other nor with the cylinder in which they are rotating. Tight clearances between the claw rotors and the housing optimise the internal seal and guarantee a consistently high pumping speed. A synchronisation gearbox ensures exact synchronisation of the claw rotors. Mink vacuum pumps are driven by a directly flange-mounted asynchronous motor, with an efficiency class IE2 / IE3.

Industrial vacuum generation for many applications

Mink claw vacuum pumps are available in a wide range of sizes. Special models for certain applications such as dust and gas explosion protection, high water vapour contents, gas tightness, increased oxygen contents etc. are also available.

- Wood industry

- Pneumatic conveying

- Transport and lifting systems

- Medical technology

- Central vacuum systems

- Packaging

- Plastics

- Food processing

- Printing

- Ceramics and brick

- Environmental technology

- Vacuum sewage

- Textiles

- Paper industry

- Beverage industry