Nội dung

MÀNG LỌC NF (NANO FILTRATION) SYNDER - USA

Nhà sản xuất: Synder - USA

Công ty Hành Trình Xanh hân hạnh là nhà nhập khẩu và phân phối chính thức sản phẩm Màng Lọc NF Synder - USA tại Việt Nam. Chúng tôi cam kết cung cấp sản phẩm và dịch vụ tốt nhất tới Quý Khách hàng.

1. Intro

Synder Filtration offers a suite of nanofiltration (NF) membranes that are engineered to provide optimal flux and rejection and can be customized to meet the unique requirements of specific process applications. Available in both spiral-wound and flat sheet membrane configurations, Synder’s nanofiltration membranes are capable of rejecting multivalent salts and larger molecules, while selectively rejecting varying amounts of monovalent salts.

Overview

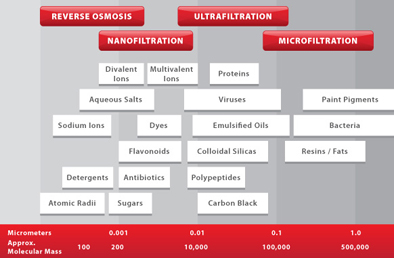

Nanofiltration is a separation process characterized by organic, thin-film composite membranes with a pore size range of 0.1 to 10nm. Unlike reverse osmosis (RO) membranes, which reject all solutes, NF membranes can operate at lower pressures and offer selective solute rejection based on both size and charge.

Degrees of Separation

Synder Filtration’s wide range of nanofiltration membranes offer varying degrees of ion selectivity to aid in the development of customized process solutions. Synder’s sanitary NF membranes are compliant with FDA standards listed in CFR Title 21, 3-A Sanitary Standards No. 45-02, as well as USDA sanitary standards and are fit for use in a variety of sanitary, as well as industrial applications across a broad spectrum of industries. If required, Synder can even develop new custom nanofiltration membranes to meet specific process goals, in partnership with our customers

With a pore size between 0.1-10nm, Synder Filtration’s nanofiltration membranes allow water and some salts to pass through the membrane while retaining multivalent ions, low molecular weight molecules, sugars, proteins, and other organic compounds. After years of research and development, Synder’s NFS, NFX, NFW, and NFG nanofiltration membrane products have been proven to offer great resistance to fouling, a high degree of selectivity, and the physical durability needed for application in a wide range of industrial separation processes. NFS, NFX, and NFW have excellent MgSO4 and lactose rejection, while NFG partially removes monosaccharides from oligosaccharides. Nanofiltration membranes overall are also able to greatly reduce levels of hardness, nitrates, sulfates, tannins, turbidity, color, TDS, and moderate levels of salt from feed water streams.

| Model | Polymer | Approx. Molecular Weight Cutoff |

Typical Operating Flux1 | Min Lactose Rejection2 | Min MgSO4 Rejection1 | Average NaCI Rejection3 |

| NFS | Proprietary PA TFC | 100-250Da | 30-40 GFD | 99.7% | 99.5% | 50-55% |

| NFX | Proprietary PA TFC | 150-300Da | 20-25 GFD | 99.0% | 99.0% | 40.0% |

| NFW | Proprietary PA TFC | 300-500Da | 45-50 GFD | 98.5% | 97.0% | 20.0% |

| NFG | Proprietary PA TFC | 600-800Da | 55-60 GFD | 60.0% | 50.0% | 10.0% |

1Test Conditions: 2,000ppm MgSO4 solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

2Test Conditions 2,000ppm Lactose Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

3Test Conditions 2,000ppm NaCI Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

NF Applications

Nanofiltration membranes are a relatively recent development, and offer greater selectivity of ions vs. reverse osmosis membranes that reject all ion species in a feed stream. This unique characteristic provides flexibility in separation process development that can greatly impact performance and profitability, especially for industrial applications.Here are some common applications of Synder’s NF membrane technology:

|

Dairy

|

|

Industrial/Wastewater Treatment

|

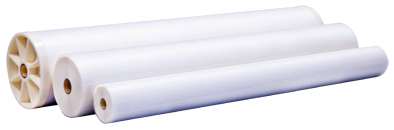

2. Nanofiltration: Flat Sheet Membranes

Nanofiltration membranes have a molecular weight cut-off range of 100 – 1000 Daltons, and reject solutes based on size and charge. NF membranes have the unique ability to reject multivalent ions, and varying degrees of monovalent ions, which is a useful tool in the process or chemical engineer’s “tool kit” of technology.

In certain high solids applications, flat sheet nanofiltration membrane provide excellent performance and membrane life vs. operating cost. Unlike hollow fiber membranes, flat sheet membranes have a very strong support material in which the polymeric membrane layer is rooted to that greatly increases physical durability.

Synder Filtration offers a complete line of dry and wet nanofiltration flat sheet membranes. With product sizes ranging from one square foot to thousands of linear feet, Synder can supply flat sheet NF membranes for process research, pilot testing, spiral element winding, and for use in plate & frame membrane systems.

| Model | Polymer | Approx. Molecular Weight Cutoff |

Typical Operating Flux1 | Min Lactose Rejection2 | Min MgSO4 Rejection1 | Average NaCI Rejection3 |

| NFS | Proprietary PA TFC | 100-250Da | 30-40 GFD | 99.7% | 99.5% | 50-55% |

| NFX | Proprietary PA TFC | 150-300Da | 20-25 GFD | 99.0% | 99.0% | 40.0% |

| NFW | Proprietary PA TFC | 300-500Da | 45-50 GFD | 98.5% | 97.0% | 20.0% |

| NFG | Proprietary PA TFC | 600-800Da | 55-60 GFD | 60.0% | 50.0% | 10.0% |

1Test Conditions: 2,000ppm MgSO4 solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

2Test Conditions 2,000ppm Lactose Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

3Test Conditions 2,000ppm NaCI Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

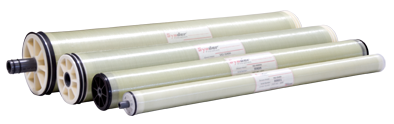

3. Nanofiltration: Spiral-Wound Elements

Nanofiltration membranes are available in many different configurations, including hollow fiber, tubular, flat sheet, and spiral-wound. When total suspended solids can be largely removed via prefiltration, Spiral-wound nanofiltration elements are often preferred because they offer a balanced combination of packing density (membrane area vs. module volume), physical durability, membrane life, and unit cost.

Nanofiltration membranes are available in many different configurations, including hollow fiber, tubular, flat sheet, and spiral-wound. When total suspended solids can be largely removed via prefiltration, Spiral-wound nanofiltration elements are often preferred because they offer a balanced combination of packing density (membrane area vs. module volume), physical durability, membrane life, and unit cost.

| Model | Polymer | Approx. Molecular Weight Cutoff |

Typical Operating Flux1 | Min Lactose Rejection2 | Min MgSO4 Rejection1 | Average NaCI Rejection3 |

| NFS | Proprietary PA TFC | 100-250Da | 30-40 GFD | 99.7% | 99.5% | 50-55% |

| NFX | Proprietary PA TFC | 150-300Da | 20-25 GFD | 99.0% | 99.0% | 40.0% |

| NFW | Proprietary PA TFC | 300-500Da | 45-50 GFD | 98.5% | 97.0% | 20.0% |

| NFG | Proprietary PA TFC | 600-800Da | 55-60 GFD | 60.0% | 50.0% | 10.0% |

1Test Conditions: 2,000ppm MgSO4 solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

2Test Conditions 2,000ppm Lactose Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

3Test Conditions 2,000ppm NaCI Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

Synder Filtration currently offers three different types of spiral wound nanofiltration elements, available in both sanitary and industrial grades and a variety of sizes. With a molecular weight cut-off between 150-300Da, NFX is the ‘tightest’ of the three with average MgSO4 and lactose rejection of 99%. NFW is the intermediary, with a molecular weight cut-off between 300-500Da and a relatively high MgSO4 and lactose rejection as well. NFG is the most open nano-membrane in the range, with a molecular weight cut-off between 600-800Da.

Synder’s sanitary nanofiltration spiral-wound elements are compliant with FDA (CFR Title 21), 3-A (Sanitary Standards No. 45-02) and USDA sanitary standards and are fit for use in a variety of food & beverage, dairy, and biotech applications. Industrial grade nanofiltration elements are also available.

Synder can customize spiral wound elements and even develop new membranes for specific application processes upon request.

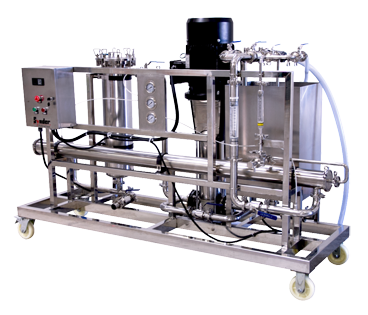

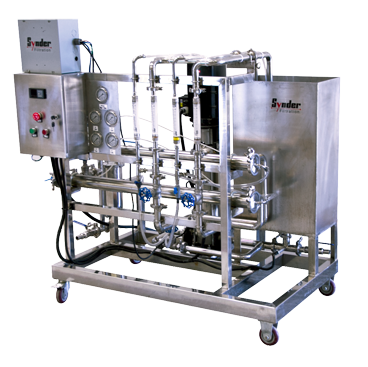

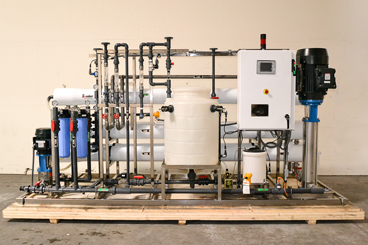

4. Nanofiltration Membrane Systems: Pilot & Full Scale

Nanofiltration systems are very similar in design to reverse osmosis systems, but can be operated with lower pressure and may require more customized features to meet specific process application requirements.

Synder Filtration designs and fabricates a wide range of nanofiltration systems, but we also help customers to develop processes through our unique and collaborative application development program.

We start by meeting with our customers to gain an understanding of their process goals. Synder’s development team then prepares a comprehensive test plan, including feasibility and pilot scale testing. Synder offers a wide array of nanofiltration pilot systems with a full range of capabilities. Some of NF pilot systems are mini-production demonstration units. See below for some examples of nanofiltration pilot units and full-scale systems.

With operating pressures up to 1,000psi and durable SS304 or SS316 stainless steel construction, pilot tests can be performed at the most extreme operating conditions. Pilot studies are conducted either at Synder’s Application Development Center in Vacaville, California, or on location at a customer’s chosen test facility.

Once the test results are collected, the engineering team engages to design the full scale membrane process solution. As a nanofiltration systems manufacturer, Synder has the capability to fabricate, install, commission and support full-scale and multi-process (RO, NF, UF, & MF) membrane systems. In every step of the process, we aim to deliver timely, knowledge, friendly service, and ultimately, application profitability for our customers.